Technics SB-M1 Introduction & Description

|

|

The Technics SB-M1 speaker system is one of the rarest high end

components of the classic early 1980's

Technics line and I think that this is the

only web page for them in existence that is written by somebody that

actually owns a pair today. My SB-M1's came to me from their first

owner who was a marketing director at a Technics studio back in that era

and these are from his personal home system. These SB-M1's are in

fact the SB-M1S studio model. They are finished in a kind of creamy

grey color and they remind me of the color of early digital telephony

switching equipment of the same era. So the first question I asked

the seller

was if he had ever seen any SB-M1(M)'s which are the beautiful rosewood

finished home version and he indicated that those were indeed around in

the USA at the time and there were some in his studio, but even he with

his big Technics discounts would not pay the extra for that beautiful

wood! The cost was literally double! What a shame (for me that is). Weighing in at a

massive 188.5 lbs each with the M versions weighing even more, they

are literally so heavy that lifting and moving them takes careful

planning if you don't want to kill yourself. Click

here for

the user manual. |

|

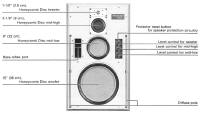

The Cabinet

The

SB-M1 cabinet is built like a tank with considerable internal bracing. The

SB-M1 cabinet is built like a tank with considerable internal bracing. It is immensely heavy and the It is immensely heavy and the baffle is made of 1-1/4 inch thick particle board. The main chamber

is a bass reflex enclosure for the woofer and there are two sealed subchambers, one for the lower mid driver, and the other for the upper mid

driver and the tweeter. All are

lined with heavy sound damping material. Even though the 4 drivers

are mounted in a vertical line the left and right side speaker cabinets

are a mirror image of each other with the bass reflex port, control panel

and Technics badge being on different

baffle is made of 1-1/4 inch thick particle board. The main chamber

is a bass reflex enclosure for the woofer and there are two sealed subchambers, one for the lower mid driver, and the other for the upper mid

driver and the tweeter. All are

lined with heavy sound damping material. Even though the 4 drivers

are mounted in a vertical line the left and right side speaker cabinets

are a mirror image of each other with the bass reflex port, control panel

and Technics badge being on different

sides. The left side sides. The left side cabinet

is the one with the Technics badge on the right and the right side cabinet

is the one with the badge on the left. Oh, so the setup in my room

is all wrong! Well my back is telling me that is how

its going to stay! There are four inset lifting handles in the back

and the two rails on the lower front called "Diffuse Poles" can also be

used for moving the SB-M1's around. I did find on my SB-M1's that

the large bolts that hold the center of each diffuse pole in place were

bottomed out and the washers were spinning around. When pulling on

the pole you could see it move in and out, so I had to add three extra

washers to each side. On the back of the cabinet although before the

days of bi-wiring speakers there are two massive terminals for connecting

the speaker wire that can easily accommodate 10 gauge cable and they match

the terminals on the back of an

SE-A3MK2. The Technics SB-M1(s) speakers do actually

have front grills even though they are most often seen with the drivers

exposed. The grills clip onto the diffuse poles to stay in place.

They have a nice angled appearance. cabinet

is the one with the Technics badge on the right and the right side cabinet

is the one with the badge on the left. Oh, so the setup in my room

is all wrong! Well my back is telling me that is how

its going to stay! There are four inset lifting handles in the back

and the two rails on the lower front called "Diffuse Poles" can also be

used for moving the SB-M1's around. I did find on my SB-M1's that

the large bolts that hold the center of each diffuse pole in place were

bottomed out and the washers were spinning around. When pulling on

the pole you could see it move in and out, so I had to add three extra

washers to each side. On the back of the cabinet although before the

days of bi-wiring speakers there are two massive terminals for connecting

the speaker wire that can easily accommodate 10 gauge cable and they match

the terminals on the back of an

SE-A3MK2. The Technics SB-M1(s) speakers do actually

have front grills even though they are most often seen with the drivers

exposed. The grills clip onto the diffuse poles to stay in place.

They have a nice angled appearance.

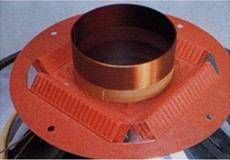

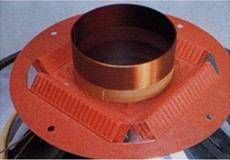

The Drivers

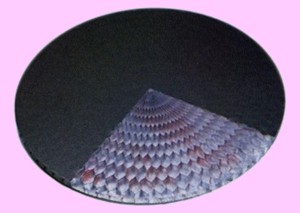

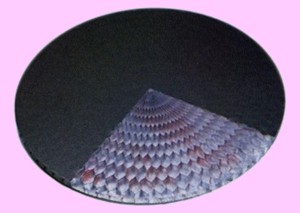

All four of the drivers are made from the same flat honey combed design

intended to make the diaphragms light but rigid. The two larger

drivers have a foam roll surround while the upper midrange unit has an

inverted surround. Difficult to say much about the tweeter as All four of the drivers are made from the same flat honey combed design

intended to make the diaphragms light but rigid. The two larger

drivers have a foam roll surround while the upper midrange unit has an

inverted surround. Difficult to say much about the tweeter as there is little to be seen except a heavy cast shield built over the

diaphragm. Producing a large high quality and high power moving coil speaker system requires

two main things of the drivers: Dissipation of the heat generated by the voice coils,

and large but light diaphragms. The power and heat dissipation is

managed in two ways, first by the division of labor in implementing a

4-way system and secondly by having a vented magnet on the three larger

drivers. In the case of the tweeter, there is a resetable fuse that

cuts the tweeter out in case of overload. These days such a tweeter

would probably have a ferro-fluid design to

there is little to be seen except a heavy cast shield built over the

diaphragm. Producing a large high quality and high power moving coil speaker system requires

two main things of the drivers: Dissipation of the heat generated by the voice coils,

and large but light diaphragms. The power and heat dissipation is

managed in two ways, first by the division of labor in implementing a

4-way system and secondly by having a vented magnet on the three larger

drivers. In the case of the tweeter, there is a resetable fuse that

cuts the tweeter out in case of overload. These days such a tweeter

would probably have a ferro-fluid design to conduct the heat away. I have to say, this is the heaviest

conduct the heat away. I have to say, this is the heaviest

tweeter I

have ever seen, 3 pounds 9 ounces to be exact! The vent on the three larger drivers goes right through the center of the magnet and the back of

the honeycomb disc can be seen through the hole. So in the case of

the bass driver, quite some air passes in and out of the driver when it is

working hard. The issue of providing a large and light diaphragm is

of course achieved with the honeycomb disc. Both the disc on either

side and the actual honeycomb appear to be made from aluminum. Then

on the back there is an aluminum cone that has about half the diameter of

the speaker where it meets the back of the disc. The magnets on each

driver are very large and heavy. The basket or frame of each driver

is made from very thick cast aluminum to maintain rigidity. Only the

15" woofer has the funky square orange suspension as shown in the

pictures. tweeter I

have ever seen, 3 pounds 9 ounces to be exact! The vent on the three larger drivers goes right through the center of the magnet and the back of

the honeycomb disc can be seen through the hole. So in the case of

the bass driver, quite some air passes in and out of the driver when it is

working hard. The issue of providing a large and light diaphragm is

of course achieved with the honeycomb disc. Both the disc on either

side and the actual honeycomb appear to be made from aluminum. Then

on the back there is an aluminum cone that has about half the diameter of

the speaker where it meets the back of the disc. The magnets on each

driver are very large and heavy. The basket or frame of each driver

is made from very thick cast aluminum to maintain rigidity. Only the

15" woofer has the funky square orange suspension as shown in the

pictures.

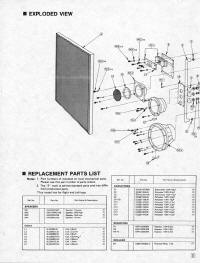

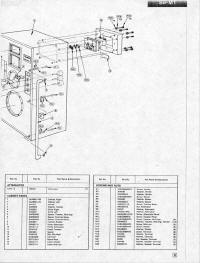

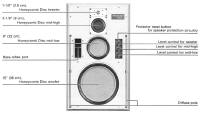

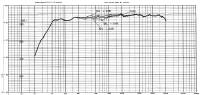

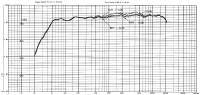

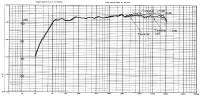

Crossovers and level adjusters

There

are two crossover boards and both are build with very heavy components to

handle all the power. The treble crossover for the tweeter There

are two crossover boards and both are build with very heavy components to

handle all the power. The treble crossover for the tweeter and

high mid range is mounted behind the speaker terminals as shown to the

right. The bass crossover for the woofer and low midrange is mounted

on the floor of the cabinet behind the woofer as shown to the lower right.

The woofer is directly connected from the bass crossover but and

high mid range is mounted behind the speaker terminals as shown to the

right. The bass crossover for the woofer and low midrange is mounted

on the floor of the cabinet behind the woofer as shown to the lower right.

The woofer is directly connected from the bass crossover but the other

three drivers each have their own level controller mounted on the front

baffle as shown to the left. This provides a range of -9dB to +1dB for

the tweeter and the mid-low driver while the mid-high has a range of -8dB to +2dB. The heavy duty rheostat style potentiometers are mounded

directly through the baffle and the face plate is just screwed over the

top of the knobs. The controls have a nice heavy feel with a soft

click for each mark on the scale. After years of sitting around, the

controls do get a bit dirty and the sound crackles a bit when they are

turned, so I cleaned them all with some switch lubricant. They can

be accessed by removing the woofer and unbolting each one in turn from the

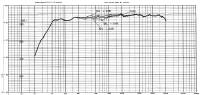

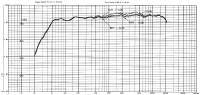

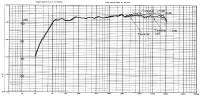

front of the baffle. The contour graphs for each

control are shown below. the other

three drivers each have their own level controller mounted on the front

baffle as shown to the left. This provides a range of -9dB to +1dB for

the tweeter and the mid-low driver while the mid-high has a range of -8dB to +2dB. The heavy duty rheostat style potentiometers are mounded

directly through the baffle and the face plate is just screwed over the

top of the knobs. The controls have a nice heavy feel with a soft

click for each mark on the scale. After years of sitting around, the

controls do get a bit dirty and the sound crackles a bit when they are

turned, so I cleaned them all with some switch lubricant. They can

be accessed by removing the woofer and unbolting each one in turn from the

front of the baffle. The contour graphs for each

control are shown below.

I have to tell you that I had considerable trouble in finding a way to

set these controls properly! Of course the proper way is to compare

the sound with a reference and adjust the controls so that the sound of

the

SB-M1's

matches the reference as closely as possible. In my opinion there is

no better reference speaker for midrange and treble than the

Quad ESL-63. Unfortunately my

original Quad's were lost by Allied Van Lines on the way to Florida so I

actually had to buy another pair on eBay in order to get the SB-M1's

properly setup. As you can see from the controls on the left, a

setting of -6, -3, +1 from the top down gives the required equalization to

match Quad ESL-63's. This also now makes my reference CD's sound

correct. This all leads me to wonder what reference the SB-M1's were

designed to and why the correct setting is not 0, 0, 0. SB-M1's

matches the reference as closely as possible. In my opinion there is

no better reference speaker for midrange and treble than the

Quad ESL-63. Unfortunately my

original Quad's were lost by Allied Van Lines on the way to Florida so I

actually had to buy another pair on eBay in order to get the SB-M1's

properly setup. As you can see from the controls on the left, a

setting of -6, -3, +1 from the top down gives the required equalization to

match Quad ESL-63's. This also now makes my reference CD's sound

correct. This all leads me to wonder what reference the SB-M1's were

designed to and why the correct setting is not 0, 0, 0.

It does mention

in the user It does mention

in the user

manual that these settings can be used to compensate for the phono cartridge being used so maybe the cartridges Technics

were shipping with SL-1200's at that time were a bit on the trebly side.

Once I was done, I resold the Quad ESL-63's to a local buyer who happened

to be a professional classical guitarist who was going to use the Quad's

as a studio reference. He commented on how close the SB-M1's sounded

compared to the Quads, so I think I have the correct setting at last!

When set incorrectly, the SB-M1's can really sound quite annoying and it

is probably the case that many potential listeners and buyers have been

put off them because of listening to them with the wrong settings.

Once set, different room settings and locations do not seem make much

difference to the sound of the upper three drivers, it is mainly the bass

that is effected. I can tell you though that when properly setup

they sound simply stunning and -6, -3, +1 is my recommended setting for

digital music sources! Obviously such large and heavy speakers have

tremendous well controlled bass and the three upper drivers do a very good

job of keeping up with the

Quad ESL-63 electrostatic reference.

The other unusual thing about the Technics SB-M1 is that even with all

these crossovers burning power and all these drivers, the average

impedance is 6 ohms rather than 8 and they are quite sensitive at 94 dB/W

at 1 meter. This means that with just an ordinary

SE-A5 they can really rock loud and

not even an SE-A3MK2 can drive

two pairs at the same time. manual that these settings can be used to compensate for the phono cartridge being used so maybe the cartridges Technics

were shipping with SL-1200's at that time were a bit on the trebly side.

Once I was done, I resold the Quad ESL-63's to a local buyer who happened

to be a professional classical guitarist who was going to use the Quad's

as a studio reference. He commented on how close the SB-M1's sounded

compared to the Quads, so I think I have the correct setting at last!

When set incorrectly, the SB-M1's can really sound quite annoying and it

is probably the case that many potential listeners and buyers have been

put off them because of listening to them with the wrong settings.

Once set, different room settings and locations do not seem make much

difference to the sound of the upper three drivers, it is mainly the bass

that is effected. I can tell you though that when properly setup

they sound simply stunning and -6, -3, +1 is my recommended setting for

digital music sources! Obviously such large and heavy speakers have

tremendous well controlled bass and the three upper drivers do a very good

job of keeping up with the

Quad ESL-63 electrostatic reference.

The other unusual thing about the Technics SB-M1 is that even with all

these crossovers burning power and all these drivers, the average

impedance is 6 ohms rather than 8 and they are quite sensitive at 94 dB/W

at 1 meter. This means that with just an ordinary

SE-A5 they can really rock loud and

not even an SE-A3MK2 can drive

two pairs at the same time.

SB-M1 Problems

Anyone

who has owned or seen a pair of Bose 901's from the 1980's will be all to

familiar with the issue of decaying foam on the surrounds of the drivers.

This issue actually completely decapitates 901's! Well there is good

news and bad news in this respect for the now quarter century old Technics

SB-M1's. The good news is that the foam surround of the 15" bass

driver is not effected. The bad news is that the 9" Mid-Low

EAS-22PL03S unit

is effected. I have heard the same thing from other SB-M1

owners. It appears that when stored for many years the units come

out looking like new, but after just a little usage the foam just crumbles

and holes start to appear. In the case of the SB-M1 Low-Mid unit,

this actually appears to make very little difference to the units

operation unlike for the Bose 901. The suspension is quite stiff

(not necessarily a good thing for a mid range driver) and it still

operates perfectly well with the entire surround crumbled and gone!

Even so, with the SB-M1's looking so good with the grills off I thought it

worth repairing them just for the cosmetic benefit and the process is

described below. Anyone

who has owned or seen a pair of Bose 901's from the 1980's will be all to

familiar with the issue of decaying foam on the surrounds of the drivers.

This issue actually completely decapitates 901's! Well there is good

news and bad news in this respect for the now quarter century old Technics

SB-M1's. The good news is that the foam surround of the 15" bass

driver is not effected. The bad news is that the 9" Mid-Low

EAS-22PL03S unit

is effected. I have heard the same thing from other SB-M1

owners. It appears that when stored for many years the units come

out looking like new, but after just a little usage the foam just crumbles

and holes start to appear. In the case of the SB-M1 Low-Mid unit,

this actually appears to make very little difference to the units

operation unlike for the Bose 901. The suspension is quite stiff

(not necessarily a good thing for a mid range driver) and it still

operates perfectly well with the entire surround crumbled and gone!

Even so, with the SB-M1's looking so good with the grills off I thought it

worth repairing them just for the cosmetic benefit and the process is

described below.

Because

of the Technics SB-M1's rarity there are no specific replacements

available for the foam surround like for the

Bose 901 and others but I have found that the generic

8" kit from Parts Express looks and works just fine even though

the driver is described as 9". The only

minor issue is that the new replacement has a better grey color than the

original foam on the 15" woofer which has a bit of a green tinge to it

although the foam there is in like new condition. Even so, it sure

makes a great improvement to the appearance of the whole speaker system. Because

of the Technics SB-M1's rarity there are no specific replacements

available for the foam surround like for the

Bose 901 and others but I have found that the generic

8" kit from Parts Express looks and works just fine even though

the driver is described as 9". The only

minor issue is that the new replacement has a better grey color than the

original foam on the 15" woofer which has a bit of a green tinge to it

although the foam there is in like new condition. Even so, it sure

makes a great improvement to the appearance of the whole speaker system.

The

process described here is not quite the same as in the Parts Express

instructions. The first step is to The

process described here is not quite the same as in the Parts Express

instructions. The first step is to remove the driver from the cabinet. This requires a 5mm hex key

(Allen key for the English). Undo one of the bottom hex bolts last

as the driver may just fall out. Make a note of which color wire is

connected to the + terminal on the speaker (Red on my units). Be

careful not to damage the flat diaphragm surface when the driver comes

out. The magnet is big and heavy and the unit is completely

unbalanced with regard to its centre of gravity! Pull off the

connectors and place the unit on its back on your work bench. Then

remove the front gasket with a screwdriver. It is just stuck on with

some glue and the whole thing has to come off. Be careful not to

damage the front surface. Although located where the front gasket is

on a regular speaker, it is not really a gasket at all but

rather a decorative trim. Clean off any foam from the back.

remove the driver from the cabinet. This requires a 5mm hex key

(Allen key for the English). Undo one of the bottom hex bolts last

as the driver may just fall out. Make a note of which color wire is

connected to the + terminal on the speaker (Red on my units). Be

careful not to damage the flat diaphragm surface when the driver comes

out. The magnet is big and heavy and the unit is completely

unbalanced with regard to its centre of gravity! Pull off the

connectors and place the unit on its back on your work bench. Then

remove the front gasket with a screwdriver. It is just stuck on with

some glue and the whole thing has to come off. Be careful not to

damage the front surface. Although located where the front gasket is

on a regular speaker, it is not really a gasket at all but

rather a decorative trim. Clean off any foam from the back.

The

next part is real messy! There will be stick and dust all over if

you are not careful! All the remaining foam has to be scraped from

the speaker basket surround and from the diaphragm surface. I found

that scraping with a craft

knife the best way to do this. The old glue on the diaphragm edge is

quite sticky and the crumbling foam mixes with it to produce a sticky

black mess. After the scraping is done, clean off any remaining old

glue with some Goof Off.

Even with the surround missing, the diaphragm is quite stable and you do

not need to use the shims provided with the kit. Even so, hold the

honeycomb disc diaphragm with your finger and thumb when scraping around

the edge. Do not let the voicecoil rub against the magnet. The

next part is real messy! There will be stick and dust all over if

you are not careful! All the remaining foam has to be scraped from

the speaker basket surround and from the diaphragm surface. I found

that scraping with a craft

knife the best way to do this. The old glue on the diaphragm edge is

quite sticky and the crumbling foam mixes with it to produce a sticky

black mess. After the scraping is done, clean off any remaining old

glue with some Goof Off.

Even with the surround missing, the diaphragm is quite stable and you do

not need to use the shims provided with the kit. Even so, hold the

honeycomb disc diaphragm with your finger and thumb when scraping around

the edge. Do not let the voicecoil rub against the magnet. It is not necessary to get a perfect finish on the diaphragm front as the

inner diameter of the new foam surround is slightly less than that of the

original, so none of the mess will show when its done.

It is not necessary to get a perfect finish on the diaphragm front as the

inner diameter of the new foam surround is slightly less than that of the

original, so none of the mess will show when its done.

After

the foam has been sufficiently cleaned, new the new foam surround can be

fitted. This is done using the lightweight contact adhesive supplied

with the kit. Contact adhesive works by being applied to both

surfaces, drying for about five minutes, then bringing the two surfaces

together into contact with each other when the adhesive is still tacky.

First apply glue to the top outer side of the new foam surround and to the

back side of the gasket where the foam will touch. The gasket makes

a snug fit over the foam surround. Leave the glue to become almost

transparent and tacky for about 5 minutes. Then fit the gasket over

the surround and press the glued surfaces together. Make sure the

foam surround is pushed all the way through the gasket all the way around.

Don't worry about any glue that shows through, it will dry clear. After

the foam has been sufficiently cleaned, new the new foam surround can be

fitted. This is done using the lightweight contact adhesive supplied

with the kit. Contact adhesive works by being applied to both

surfaces, drying for about five minutes, then bringing the two surfaces

together into contact with each other when the adhesive is still tacky.

First apply glue to the top outer side of the new foam surround and to the

back side of the gasket where the foam will touch. The gasket makes

a snug fit over the foam surround. Leave the glue to become almost

transparent and tacky for about 5 minutes. Then fit the gasket over

the surround and press the glued surfaces together. Make sure the

foam surround is pushed all the way through the gasket all the way around.

Don't worry about any glue that shows through, it will dry clear.

Next

after the gasket and surround have dried for about an hour, the gasket and

surround can be glued to the basket and diaphragm at the same time.

Don't try to do this in two separate steps! Try putting the gasket

and surround in place to see how it will look and make sure everything is

OK. The gasket has 8 locators to lock it in place. Next remove

the gasket and surround and apply glue to the inner back rim of the foam

surround ONLY. Immediately with the glue still wet and white, lock

the gasket into position on the speaker basket and then lift the diaphragm

a little from underneath so it touches the wet glue on the back of the Next

after the gasket and surround have dried for about an hour, the gasket and

surround can be glued to the basket and diaphragm at the same time.

Don't try to do this in two separate steps! Try putting the gasket

and surround in place to see how it will look and make sure everything is

OK. The gasket has 8 locators to lock it in place. Next remove

the gasket and surround and apply glue to the inner back rim of the foam

surround ONLY. Immediately with the glue still wet and white, lock

the gasket into position on the speaker basket and then lift the diaphragm

a little from underneath so it touches the wet glue on the back of the surround all the way around. Then immediately remove the gasket and

surround. Now you will see a white ring of glue on the diaphragm

edge in the exact right location. Swab it around and add any extra

glue needed. Now apply glue to the outer back side of the gasket and

to the speaker basket. Reapply any extra needed glue to the inner

rim of the back of the foam surround and to the front of the diaphragm

edge where the glue mark was previously made. Don't add too much

glue so it goes more to the center of the front of the diaphragm as it

will be seen when the job is complete. Leave the glue to become

almost transparent and tacky for about 5 minutes. Then press the

gasket and surround back onto the speaker basket and lock into place.

With finger and thumb, gently go all around the diaphragm bottom and foam

top and press them together. Don't worry if a small amount of glue

is squeezed out as it will dry transparently. After about an hour,

the speaker can be replaced in the cabinet and tested.

surround all the way around. Then immediately remove the gasket and

surround. Now you will see a white ring of glue on the diaphragm

edge in the exact right location. Swab it around and add any extra

glue needed. Now apply glue to the outer back side of the gasket and

to the speaker basket. Reapply any extra needed glue to the inner

rim of the back of the foam surround and to the front of the diaphragm

edge where the glue mark was previously made. Don't add too much

glue so it goes more to the center of the front of the diaphragm as it

will be seen when the job is complete. Leave the glue to become

almost transparent and tacky for about 5 minutes. Then press the

gasket and surround back onto the speaker basket and lock into place.

With finger and thumb, gently go all around the diaphragm bottom and foam

top and press them together. Don't worry if a small amount of glue

is squeezed out as it will dry transparently. After about an hour,

the speaker can be replaced in the cabinet and tested.

Well now that I'm looking at it I see that the four foam surrounds

provided in the Parts Express kit are in fact two different pairs.

The other pair are of a slightly lower profile and also a bit darker in

color. Those would have probably been a better match with the

surround on the woofer of the SB-M1's but I guess I'll just leave them as

they are now. I can always change them again later if I need to.

So at the very least, you should make sure you have a proper pair before

you start.  Knowing

this, you can just about see the two different pairs in the photo above. Knowing

this, you can just about see the two different pairs in the photo above.

SB-M1(s) Specifications

| Type |

4 way 4 speaker system |

| Woofer EAS-38PL32S |

15" (38 cm) Honeycomb Disc |

| Mid-low EAS-22PL03S |

9" (22 cm) Honeycomb Disc |

| Mid-High EAS-12PM216S |

3-1/8" (8 cm) Honeycomb Disc |

| Tweeter EAS-3PH10S |

1-1/8" (2.8 cm) Honeycomb Disc |

| Impedance |

6 ohms |

| Input Power Music |

350W |

| Input Power DIN |

150W |

| Output Sound Pressure |

94 dB/Watt at 1 meter |

| Crossover Frequencies |

280Hz, 900Hz, 4000Hz |

| Frequency Range |

25Hz~38kHz (-16dB)

35Hz~35kHz (-10dB) |

| Dimensions |

24-13/16" (W) x 41-11/32 (H) x 17-9/32" (D)

63.0 (W) x 105.0 (H) x 43.9 (D) cm |

| Weight |

188.5 lbs (85.5 kg) |

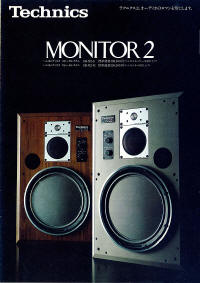

SB-M2

Well

another way to avoid the problems of the EAS-22PL03S Mid-Low driver is to

go for SB-M2's rather than the M1. These slightly smaller speakers

are effectively the same as the SB-M1 although slightly shorter and are a

3-way design without the EAS-22PL03S driver. The power handling is

reduced from 150 watts to 130 watts and the crossover frequencies are

750Hz and 4kHz. So for the tweeter everything is the same as for the

SB-M1 but now the Mid-High (or just Mid in this case) EAS-12PM216S has to

go down to 750Hz from 900Hz and the EAS-38PL32S woofer has to go all the

way up to 750Hz from just 280Hz on the SB-M1. Although I don't know,

I would venture to say that the SB-M2's probably sound better than the

SB-M1 just because there are less crossovers and drivers. If you

know anything about this, please let

me know. Well

another way to avoid the problems of the EAS-22PL03S Mid-Low driver is to

go for SB-M2's rather than the M1. These slightly smaller speakers

are effectively the same as the SB-M1 although slightly shorter and are a

3-way design without the EAS-22PL03S driver. The power handling is

reduced from 150 watts to 130 watts and the crossover frequencies are

750Hz and 4kHz. So for the tweeter everything is the same as for the

SB-M1 but now the Mid-High (or just Mid in this case) EAS-12PM216S has to

go down to 750Hz from 900Hz and the EAS-38PL32S woofer has to go all the

way up to 750Hz from just 280Hz on the SB-M1. Although I don't know,

I would venture to say that the SB-M2's probably sound better than the

SB-M1 just because there are less crossovers and drivers. If you

know anything about this, please let

me know.

Pictures & Reference

Technics SB-M1 Speakers For Sale

I sometimes have SB-M1's for sale that I have refurbished or acquired by

other means. If there are

any, the following pages are what I prepare for eBay auctions and these items

may or may not be currently listed for sale on eBay but you can find out by

clicking

here to see my current eBay auctions. If you would like to buy a pair

that is listed here

please let me know. I accept payments by credit card (PayPal), cashiers check or money

order. If you have a pair of Technics SB-M1's that you would like to sell

in the USA,

please let me know and I'll come and pick them up!

SOLD

Technics SB-M1(S) SOLD

SOLD

Technics SB-M1(S) BA2216A017 &

SB-M1(S) BA2216A018 SOLD

|

All four of the drivers are made from the same flat honey combed design

intended to make the diaphragms light but rigid. The two larger

drivers have a foam roll surround while the upper midrange unit has an

inverted surround. Difficult to say much about the tweeter as

All four of the drivers are made from the same flat honey combed design

intended to make the diaphragms light but rigid. The two larger

drivers have a foam roll surround while the upper midrange unit has an

inverted surround. Difficult to say much about the tweeter as there is little to be seen except a heavy cast shield built over the

diaphragm. Producing a large high quality and high power moving coil speaker system requires

two main things of the drivers: Dissipation of the heat generated by the voice coils,

and large but light diaphragms. The power and heat dissipation is

managed in two ways, first by the division of labor in implementing a

4-way system and secondly by having a vented magnet on the three larger

drivers. In the case of the tweeter, there is a resetable fuse that

cuts the tweeter out in case of overload. These days such a tweeter

would probably have a ferro-fluid design to

there is little to be seen except a heavy cast shield built over the

diaphragm. Producing a large high quality and high power moving coil speaker system requires

two main things of the drivers: Dissipation of the heat generated by the voice coils,

and large but light diaphragms. The power and heat dissipation is

managed in two ways, first by the division of labor in implementing a

4-way system and secondly by having a vented magnet on the three larger

drivers. In the case of the tweeter, there is a resetable fuse that

cuts the tweeter out in case of overload. These days such a tweeter

would probably have a ferro-fluid design to conduct the heat away. I have to say, this is the heaviest

conduct the heat away. I have to say, this is the heaviest

tweeter I

have ever seen, 3 pounds 9 ounces to be exact! The vent on the three larger drivers goes right through the center of the magnet and the back of

the honeycomb disc can be seen through the hole. So in the case of

the bass driver, quite some air passes in and out of the driver when it is

working hard. The issue of providing a large and light diaphragm is

of course achieved with the honeycomb disc. Both the disc on either

side and the actual honeycomb appear to be made from aluminum. Then

on the back there is an aluminum cone that has about half the diameter of

the speaker where it meets the back of the disc. The magnets on each

driver are very large and heavy. The basket or frame of each driver

is made from very thick cast aluminum to maintain rigidity. Only the

15" woofer has the funky square orange suspension as shown in the

pictures.

tweeter I

have ever seen, 3 pounds 9 ounces to be exact! The vent on the three larger drivers goes right through the center of the magnet and the back of

the honeycomb disc can be seen through the hole. So in the case of

the bass driver, quite some air passes in and out of the driver when it is

working hard. The issue of providing a large and light diaphragm is

of course achieved with the honeycomb disc. Both the disc on either

side and the actual honeycomb appear to be made from aluminum. Then

on the back there is an aluminum cone that has about half the diameter of

the speaker where it meets the back of the disc. The magnets on each

driver are very large and heavy. The basket or frame of each driver

is made from very thick cast aluminum to maintain rigidity. Only the

15" woofer has the funky square orange suspension as shown in the

pictures.

There

are two crossover boards and both are build with very heavy components to

handle all the power. The treble crossover for the tweeter

There

are two crossover boards and both are build with very heavy components to

handle all the power. The treble crossover for the tweeter